Do you know how to produce pp. Plastic flat yarn also known as cutting fiber it is the basic material of plastic.

The Complete Guide To Pp Woven Sacks Sapphire Packaging Co Ltd Reusable Shopping Bag Manufacturer

2022 China Factory Big Green PP Woven Bag for Express Delivery Find details about China White PP Woven Bag Polypropylene Woven Bag from 2022 China Factory Big Green PP Woven Bag for Express Delivery - Qingdao Sentany International Trading Co Ltd.

. Following are the relative knowledge about flat yarn. Each crafts measure ought to be run by engineers to guarantee the product quality. We can make as many as 70000 bags an hour depending on the size of the poly bags were producing.

According to the different equipment applied it can be. Our Process Ganpati Plastfabs manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins and every bag is quality checked before being packed and shipped. Our BOPP Bags And PP Woven Bags Are Durable UV-Resistant And Customized To Your Needs.

Woven Sack Bags Making Machine Main Parameter. Circular weaving machine of hdpe pp fabric - the circular looms have variable weaving density greater weft capacity and maximum productivity with. We are offering a complete process of pp woven bags manufacturing service main process includes pp extruding circular weaving flexo printing gravure printing lamination bags cutting LDPEHDPE inserting gusseting bags sewing etc.

Production method of 2-in-1 or 3-in-1 laminated Polypropylene woven bags are to compound the film or paper onto PP woven fabric. Ad Proud To Help Businesses Around The Globe Transport Their Goods Save Money Doing It. PP Woven Bag Machine Production Process.

The roll cloth or sheet cloth obtained can be cut printed sewn and made into common sewing bottom bags and can also be punched folded cut printed sewn and made into cement bags. Production process of non-woven bag. 1 PP Woven bags Uncoated Its production process is.

Non-woven shopping bag production process. The original tubular PP woven fabric is processed into woven bag through printing cutting sewing and other steps. The obtained tubular cloth or sheet cloth can be cut printed sewn and made into ordinary sewing bag and can also be punched folded cut printed and sewed into cement bag.

Complete quality management systems are strictly followed at each step of the manufacturing process. Following we will briefly talk about the investment that the pp woven bag processing factory needs which is oriented by the demand of the middle and low-end woven bags. Non-woven punching bag production and printing process.

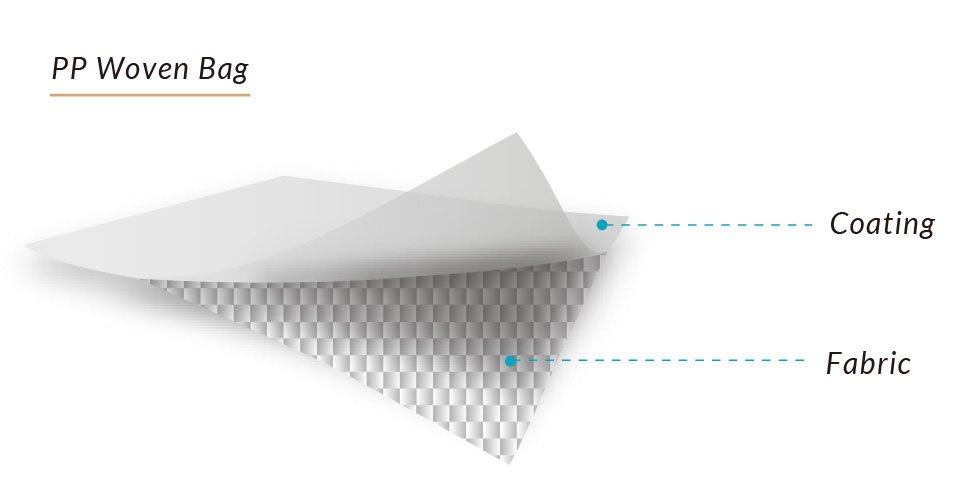

Roller diameter 1200mm. Non-woven bag production process. The production technology of composite PP woven bags is to composite or coat the weave fabric coating material and paper or film together.

The production technology of composite PP woven bags is to composite or coat the weave fabric coating material and paper or film together. Tourism and transport You will also see PP woven fabrics used as sunshades temporary tents and even as fences and screens. In terms of the crafts process it is the most basic part throughout the production process.

Our BOPP Bags And PP Woven Bags Are Durable UV-Resistant And Customized To Your Needs. Here we have depicted production process of woven bag using LDPHDP which is extracted from fossil fuel and crude oil and use as raw materials in such fact. Search Products Suppliers Product Directory Supplier Discovery Post Sourcing Request.

Woven polypropylene sandbags are often essential for the construction of river banks dams and other such projects. 2020-03-15 An entire set of production procedure of pp spunbond nonwoven fabric needs to be performed from raw materials introduction to completed product sales. PP Woven Sack Cutting Sewing Production Line.

1 or 2sets of sewing and cutting machine 2 in 1 machine. We are a one-stop solution for FIBC. Our manufacturing process of woven polypropylene bags use only pure virgin polypropylene resins and nearly every bag is even visually checked at last before packed.

The first production process of woven bag is flat yarn making drawing which determines the quality of pp woven bag base fabric. Flood control products PP woven bags are crucial in reducing the detrimental effects of flooding. The roll cloth or sheet cloth obtained can be cut printed sewn and made into common sewing bottom bags and can also be punched folded cut printed sewn and made into cement bags.

However if we are manufacturing larger bags we may only be able to produce 2000 bags an hour. Poly bag production speed does depend on the size and thickness of the bags youre looking for but in general its a very fast process. Production process of non-woven bag.

Ad Proud To Help Businesses Around The Globe Transport Their Goods Save Money Doing It. This includes wire drawing fabric weaving extrusion lamination gravure printing bag forming bag sewing quality testing and customer service. Using PP woven bags PP non woven bags is becoming increasingly popular with reasonable cost environmental and can be reused.

Around 20000USD per set some model with lower mechanical properties would costs 16000-18000 USDSET.

The Complete Guide To Pp Woven Sacks Sapphire Packaging Co Ltd Reusable Shopping Bag Manufacturer

Production Process Of Polypropylene Weaving And Pp Woven Bags Making Wenzhou Morn Packaging Co Ltd

Best Use Of Polypropylene Woven Bags In Delhi Dns Group Woven Bag Fabric Bags Woven

Hot Item Custom Luxury Advertising Pp Non Woven Fabric Packing Bag In 2022 Non Woven Bags Luxury Advertising Woven

Pp Woven Bags Manufacturer Supplier Dns Group Woven Bag Woven Bags

Manufacturing Process Of Pp Woven Bags Wenzhou Morn Packaging Co Ltd

0 comments

Post a Comment